Description

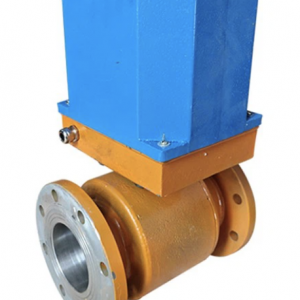

1/2 Inch Three Way CF8 Motorized Ball Valve is a new type of three-way port switching ball valve, which can be used to control the direction, diversion, or convergence of the medium in three pipelines. According to the different ball core structures, it can be divided into T-shaped or L-shaped. The difference between T-shaped electric three-way ball valve and L-shaped electric three-way ball valve is mainly due to the difference in internal structure, which cannot be seen from the appearance! T-shaped ball valves can connect and cut off the third channel of three orthogonal pipelines, playing a role in diversion and convergence, while L-shaped ball valves can only connect the two orthogonal pipelines and cannot maintain the interconnection of the third pipeline at the same time, only playing a role in distribution.

Features

◆ Reduced diameter T-shaped/L-shaped/X-shaped: 1/2-6 (DN15-DN150)

◆ Work pressure: Class 150/300 PN16/40 10K Working temperature: -20C~180C

◆ American standard ANSI Class 150 Design standard: ASME B16.34API608API6D

◆ Design of explosion-proof valve stem outlet device

◆ flange standard: ASME B16.51 Dynamic load design of double butterfly springs

◆ Inspection&Testing: AP1 598

◆ Precision casting

◆ Anti static device (optional)

◆ 4 valve seat designs

◆ 360 ° rotating handle

◆ Lock handle

◆ ISO5211 Direct Mount High Platform Design

◆ Automation device (optional)

◆ German standard DIN PN16 Design standard: EN1983EN12516-1

◆ flange standard: EN1092-1 PN16/40

◆ Inspection&Testing: EN12266-1 Japanese standard: JIS 10K Design standard: JIS B2071

◆ Flange standard: JIS B2220 Inspection&Testing: JIS B2003

In terms of technology, T-shaped electric three-way ball valves can replace L-shaped electric three-way ball valves, but L-shaped ball valves cannot replace T-shaped ball valves! During use, different structural forms should be selected according to different working conditions, and T-shaped ball valves can be used for direct current, while L-shaped ball valves cannot.

The three-way ball valve can flexibly cut, distribute, and change the flow direction of the medium. The sealing surface of a ball valve is usually in a closed state with the spherical surface, so it is not easily eroded by the medium, easy to operate, and has a simple and compact structure. It can be used in working conditions with water, natural gas, acid, solvents, etc.