Description

Basic Information

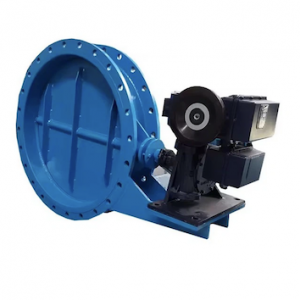

The 30inch Flange Casting Damper Valve is mainly designed and manufactured with a new structure of centerline butterfly plate and short structural steel plate welding. It has compact structure, light weight, easy installation, small flow resistance, large flow volume, avoids the influence of high temperature expansion, and is easy to operate. There is no connecting rod, bolt, etc. in the body, reliable operation, long service life. It can be installed in multiple positions and is not affected by the flow direction of the medium.

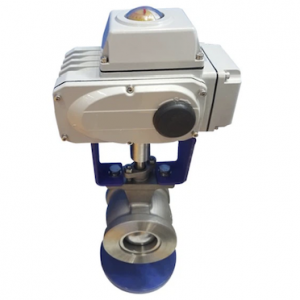

Name: Electric damper valve

Control mode: On-off type

Specification: DN40-dn1200

Power supply voltage: 220v, 380v

Structural features

1. It is convenient and quick to open and close, labor-saving, with low fluid resistance, and can be operated frequently.

2. It has a simple structure, small external dimensions, short structural length, small volume, and light weight, and is suitable for large-diameter valves.

3. It can transport mud, and the liquid is minimally accumulated at the pipe mouth.

4. Good sealing can be achieved under low pressure.

5. Good adjustment performance.

The butterfly valve has the characteristics of simple structure, small size, light weight, low material consumption, small installation size, fast switching, 90° reciprocating rotation, and small driving torque. It is used to cut off, connect, and adjust the medium in the pipeline, and has good fluid control characteristics and closing and sealing performance.

The butterfly valve can transport mud and accumulate the least amount of liquid at the pipe mouth. It can achieve good sealing under low pressure. It has good adjustment performance. The streamlined design of the butterfly plate reduces the fluid resistance loss and can be regarded as an energy-saving product.

The valve stem is a through-stem structure, which has been tempered and has good comprehensive mechanical properties, corrosion resistance and abrasion resistance. When the butterfly valve is opened and closed, the valve stem only rotates but does not move up and down. The packing of the valve stem is not easy to be damaged and the seal is reliable. It is fixed with the butterfly plate taper pin, and the extended end is designed to prevent the valve stem from collapsing when the connection between the valve stem and the butterfly plate is accidentally broken.

The angle from fully open to fully closed of a butterfly valve is usually less than 90°. The butterfly valve and butterfly stem themselves do not have self-locking capabilities. In order to position the butterfly plate, a worm gear box must be installed on the valve stem. The use of a worm gear box can not only make the butterfly plate self-locking and stop the butterfly plate at any position, but also improve the operating performance of the valve. Features of industrial butterfly valves: High temperature resistance, high applicable pressure range, large valve nominal diameter, valve body made of carbon steel, and valve plate sealing ring made of metal ring instead of rubber ring. Large high-temperature butterfly valves are made of steel plate welding and are mainly used in smoke and air ducts and gas pipelines for high-temperature media.

Instructions for damper valve

The structural design of the damper butterfly valve should be combined with the working conditions of the valve.

1. Under the smelting conditions with high temperature and large dust content, the design of the damper butterfly valve can adopt a flat inclined plate structure. There is a gap between the butterfly plate and the valve body of this structure. The gap value depends on the valve caliber and process. The conditions of use are determined, and are generally controlled within 0.5% of its channel area, which can meet the installation of damper butterfly valves, temperature changes in working conditions, and melting process requirements.

2. Under acid-making working conditions with high temperature and low dust content, the damper butterfly valve can be designed with a vertical plate structure. The sealing surface of this structure is easy to process, and the sealing surface gap value is controlled within 0.2% of the channel area. The dimensional accuracy of the valve body and butterfly plate seal pair can meet the design requirements through mechanical processing.

3. For working conditions with high temperature, low pressure and strict sealing requirements, the damper butterfly valve is designed to adopt a lever-type planar structure. The sealing pair configuration and butterfly plate running trajectory can meet the process requirements of pipe network equipment with high sealing performance.

The main seal of the damper butterfly valve adopts different structures according to different working conditions, which is beneficial to valve production and working conditions. The shaft end structure design of the damper butterfly valve adopts an external support structure with excellent heat insulation and sealing effects, which can realize the function of sealing first and then supporting the two shaft ends of the valve, making it easy to adjust without causing shaft end jamming. When the direct-connected or crank connecting rod mechanism is connected to the transmission mechanism, the installation of a heat insulation sleeve can effectively distance the impact of the high temperature environment on the transmission device and ensure the normal operation of the valve. The valve body and butterfly plate of the large-diameter ventilation butterfly valve should be cast or welded according to the requirements of the working conditions. Both should be equipped with ribs. Reasonable process plans and materials should be selected to improve the rigidity of the product and prevent product deformation.

Precautions for damper valve

The installation position of the damper butterfly valve in the pipe network and the layout of the pipe network also have an impact on the use of the valve. Pipes with large smoke and dust are designed with a closed funnel at the valve opening end or the valve connection corner. Regular dust removal can prevent excessive dust accumulation, which is beneficial to The rotation of the butterfly plate. Several issues should be paid attention to when installing damper butterfly valves

1. When using metal gaskets, the load must be ensured to avoid the influence of temperature and dead weight or the stress caused by welding from bringing additional pressure to the valve and deforming the valve flange and pipeline.

2. When the valve is installed in a long pipeline, a support frame should be installed.

3. When installing the valve, attention should be paid to the flow direction of the medium, so that the opening direction of the butterfly plate is consistent with the flow direction of the pipeline medium, which is conducive to the self-cleaning effect of the medium flow rate. 4. Strengthen the protection of the overall insulation layer of the pipe network to keep the pipe wall temperature above the dew point, which can reduce low-temperature adhesive dust accumulation. If the pipe wall temperature is higher than the acid dew point of the flue gas, it can avoid the condensation of acid vapor on the heated pipe wall and control the generation rate of sulfur trioxide, so the valve will be more effective.

Damper butterfly valves can be installed in different positions depending on the design of the pipeline, such as horizontally, vertically, and at corners. Generally, damper butterfly valves installed on vertical pipes have better results and are less likely to accumulate dust, followed by horizontal pipes, and corners have the worst effect. The corners on both sides of the valve inlet and outlet are most likely to cause bias flow and dust blockage, and the valve operating torque will increase.