Description

CF8 A351 Female Thread Electric Ball Valve and butt welded connection ball valves are divided into integral (integral), two-stage, and three-stage types. The valve body casting adopts advanced technology imported from Taiwan, with a reasonable structure and beautiful appearance. The valve seat adopts an elastic sealing structure, which is reliable and easy to start. The valve stem adopts a bottom mounted structure with an inverted seal.

● Full diameter, 1/4"~4(DN6~DN100)

● Working pressure W.P.:1000WOG(PN63)

● Working temperature W.T.:-20C~180C

● Precision casting

● Valve stem explosion-proof device design

● Handle lock device (optional)

● Thread connection standard: ASME B1.20.1(NPT)DIN 259 / DIN 2999,BS 21ISO 288-1,IS0 7-1

The Use Of Ball Valve

Since ball valves usually use rubber, nylon and polytetrafluoroethylene as seat sealing ring materials, their service temperature is limited by the seat sealing ring material. The cut-off function of the ball valve is accomplished by the metal balls pressing against each other between the plastic valve seats under the action of the medium (floating ball valve). Under the action of a certain contact pressure, the valve seat sealing ring will undergo elastic-plastic deformation in local areas. This deformation can compensate for the manufacturing accuracy and surface roughness of the ball and ensure the sealing performance of the ball valve. And because the seat sealing ring of a ball valve is usually made of plastic, when selecting the structure and performance of the ball valve, the fire resistance and fire prevention of the ball valve must be considered, especially in petroleum, chemical industry, metallurgy and other departments, in flammable and explosive media When ball valves are used in equipment and piping systems, more attention should be paid to fire resistance and fire prevention.

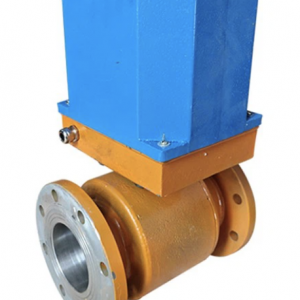

Electric threaded ball valve

The electric threaded ball valve adopts an integrated structure and is matched with the electric actuator. It can operate by inputting a (4-20mA DC, 0-10V DC or 1-5V) signal or single-phase power supply. It has strong functions, small size, light weight and low cost. , reliable performance, simple matching, large circulation capacity and other characteristics. At present, the valve is widely used in industrial automation control systems in food, environmental protection, light industry, petroleum, papermaking, chemical industry, teaching and scientific research equipment, electric power and other industries.

Electric threaded ball valves and butt welded ball valves are divided into integral (one-piece), two-stage and three-stage types. The valve body is cast using advanced technology introduced from Taiwan. It has a reasonable structure and beautiful appearance. The valve seat adopts an elastic sealing structure, which is reliable in sealing and easy to start. The valve stem adopts a bottom-mounted structure with an inverted seal. When the valve cavity heats up abnormally, the valve stem will Will not be impacted. Two-piece and three-piece ball valves also have butt welding (BW) and socket welding (SW) connection forms. They can also be equipped with international standard ISO bracket platforms and locking devices.

Features

Electric threaded ball valves and butt welded ball valves are divided into integral (one-piece), two-stage and three-stage types. The valve body is cast using advanced technology introduced from Taiwan. It has a reasonable structure and beautiful appearance. The valve seat adopts an elastic sealing structure, which is reliable in sealing and easy to start. The valve stem adopts a bottom-mounted structure with an inverted seal. When the valve cavity heats up abnormally, the valve stem will Will not be impacted. Two-piece and three-piece ball valves also have butt welding (BW) and socket welding (SW) connection forms. They can also be equipped with international standard ISO bracket platforms and locking devices.