Description

DLC DN40 Stainless Steel Electric Control Valve is mainly used in industrial systems and can also be used in the HVAC field. It is equipped with an intelligent valve actuator control system and has powerful expansion functions and reliable stability.

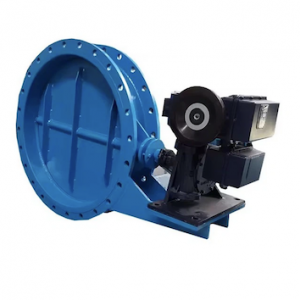

Digital (intelligent) electric valve actuator

Max. thrust: 1000N 2000N 3000N 5000N 6500N 10000N 16000N 20000N 26000N

Valve position feedback

4-20mA, 0-10V, RS485 optional, (open/close in position feedback optional)

Protection level

IP65 IP67

Technical parameter

It is mainly used in industrial systems and can also be used in the HVAC field. It is equipped with an intelligent valve actuator control system and has powerful expansion functions and reliable stability.

Valve component materials

Main methods of hardening treatment

Commonly used valve internal component materials are SUS304, SUS316, SUS316L, SUS410, SUS420, etc., and are processed accordingly according to different fluid conditions. For controlling cavitation fluids, fluids containing solid particles, and high-temperature and high-pressure situations, they must be hardened. treatment to extend the service life of the valve.

Heat treatment

a.304/316 solid solution treatment This series of materials is austenitic stainless steel and is mainly used in working conditions where the medium is corrosive or in low-temperature situations. When the medium is highly corrosive, solution treatment must be carried out. The purpose of solution treatment is to improve the hardness and corrosion resistance of the material. Temperature range -196~530°C

b.410/420 quenching and tempering treatment (quenching + tempering) The material of this series is martensitic stainless steel, which is an excellent cavitation-resistant material. It must be quenched and tempered when used in high-temperature and high-pressure difference situations. The purpose of quenching and tempering treatment is to greatly improve the hardness of the material and extend its service life under harsh working conditions. Temperature range -45~425°C

c.17-4PH precipitation hardening treatment Different types and quantities of strengthening elements are added to the chemical composition of stainless steel, and different types and quantities of carbides, nitrides, carbides and intermetallic compounds are precipitated through the precipitation hardening process, which not only improves the strength of the steel but maintains sufficient toughness. A type of high-strength stainless steel, referred to as precipitation hardening. Temperature range -45~425°C

Surface hardening treatment

Surface heat treatment is divided into two categories: surface quenching and surface chemical heat treatment. a. Flame heating surface quenching, contact electric heating surface quenching, induction heating surface quenching, etc. b. Carburizing, nitriding, carbonitriding, chromium boronizing, copper infiltrating, etc.

Surfacing treatment

Stellite cladding (main components Co, Cr, W) is a commonly used hardening treatment method with excellent corrosion resistance. There are two methods of Stellite surfacing: full surfacing and partial surfacing. There is no standard regulation for the specific surfacing method. It usually depends on the different pressures and temperatures of the fluid and whether the fluid contains particles. The types of surfacing welding are as follows:

working principle and characteristics

1. The control valve is simple to control and intrinsically safe. No additional explosion-proof measures are required

2. The servo amplifier adopts deep dynamic negative feedback, which can improve the accuracy of automatic adjustment.

3. The fluid acts on the valve core in all directions, so the valve can work stably.

4. All movable surfaces use high-quality bearings with low friction, long life and no noise.

5. The regulating valve has superb technology, superior structure, smooth flow, quick response, and can replace imported goods.

6. The pressure drop loss of the regulating valve is small, the output force is stable, the flow coefficient is large, and the smooth cross-sections of the channels are equal.

7. The regulating valve adopts a pressure balance mechanism inside the valve, which makes the regulating valve responsive, precise in control, and allows a large pressure difference.

8. The regulating valve body is designed according to the principle of fluid mechanics with a low-flow resistance passage of equal cross-section, and the rated flow coefficient is increased by 30%.

9. The regulating valve has the characteristics of small size, light weight, easy to use, large flow, energy saving, and high adjustment accuracy.