Description

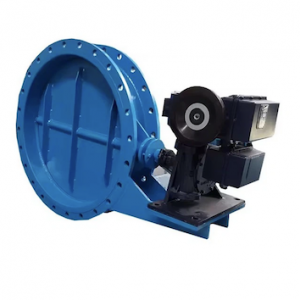

DN400 16 inch Wafer Butterfly Valve has the characteristics of simple structure, small size, light weight, low material consumption, small installation size, fast switching, 90° reciprocating rotation, small driving torque, etc. It is used to cut off, connect and adjust the medium in the pipeline, and has good fluid control characteristics and closing sealing performance. When the butterfly valve is in the fully open position, the thickness of the butterfly plate is the resistance of the medium flowing through the valve body, so the pressure drop generated by the valve is very small, so it has good flow control characteristics. Butterfly valves have two sealing types: soft seal and metal seal. For soft seal valves, the sealing ring can be embedded in the valve body or attached to the periphery of the butterfly plate.

Valves with metal seals generally have a longer life than valves with soft seals, but it is difficult to achieve complete sealing. Metal seals can adapt to higher operating temperatures, while soft seals have the defect of being limited by temperature.

If the butterfly valve is required to be used as a flow control, the main thing is to correctly select the size and type of the valve. The structural principle of the butterfly valve is particularly suitable for making large-diameter valves. Butterfly valves are not only widely used in general industries such as petroleum, gas, chemical industry, and water treatment, but also in the cooling water system of thermal power plants.

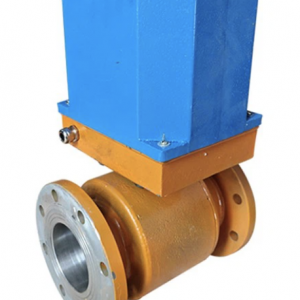

Commonly used butterfly valves include wafer-type butterfly valves, flange-type butterfly valves, and butt-weld butterfly valves. Wafer-type butterfly valves use stud bolts to connect the valve between two pipe flanges; flange-type butterfly valves have flanges on the valve, and the flanges on both ends of the valve are connected to the pipe flanges with bolts; butt-weld butterfly valves have both ends welded to the pipe.

Technical parameters

· Nominal diameter, DN50-DN3000 (2"-120")

· Pressure: PN6-PN16 (clss150)

· Working temperature: 20°C-200C +

· Connection method: wafer type

Main materials

· Valve body: ductile iron, carbon steel, stainless steel

· Valve plate: ductile iron, stainless steel, alloy steel, etc.

· Valve seat: EPDM, NBR VITON, etc.

Advantages

1. Opening and closing is convenient and quick, labor-saving, and the fluid resistance is small, so it can be operated frequently.

2. The structure is simple, the external dimensions are small, the structural length is short, the volume is small, and the weight is light, which is suitable for large-diameter valves.

3. It can transport mud, and the liquid is accumulated at the pipe mouth at a minimum.

4. Under low pressure, a good seal can be achieved.

5. Good adjustment performance.

6. When fully open, the effective flow area of the valve seat channel is large, and the fluid resistance is small.

7. The opening and closing torque is small. Since the butterfly plates on both sides of the rotating shaft are basically affected by the medium, and the direction of the torque is opposite, it is easier to open and close.

8. The sealing surface material is generally made of rubber and plastic, so the low-pressure sealing performance is good.

9. Easy to install.

10. Flexible and labor-saving operation, manual, electric, pneumatic, and hydraulic methods can be selected.

Features ·

· Fully rubber-lined valve body design

· Through shaft without pin, arc valve plate

· Two-way pressure bearing, two-way sealing

· Stem triple seal

· A variety of material configurations, application of different media

Overview application

· Centerline rubber-lined media valves are widely used in power, metallurgy, chemical, food, municipal, and electric power systems as cut-off or regulating devices for liquid, gas, and semi-fluid pipelines, such as wet desulfurization, water treatment, fire protection, and municipal piping etc.