Description

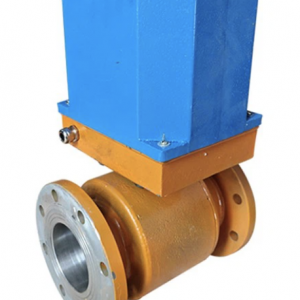

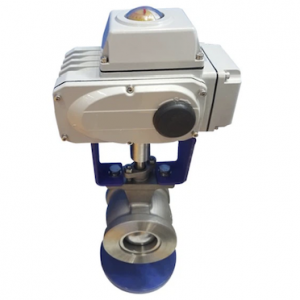

This series of dust and gas Low Pressure Air Duct Butterfly Damper Valves have various driving methods and can be adapted to different environmental conditions. They are widely used in gas, flue gas, air pipelines and environmental protection and dust removal facility systems in metallurgy, chemical industry, machinery, cement, electricity and other industries.

Produce Features

The main features are good erosion resistance, small opening and closing torque, flexible movement, short structure, and light weight. It is especially suitable for cutting and adjusting pipelines with high system temperature, large dust content in the medium, and frequent operations. This series of dust and gas butterfly valves have various driving methods and can be adapted to different environmental conditions. They are widely used in gas, flue gas, air pipelines and environmental protection and dust removal facility systems in metallurgy, chemical industry, machinery, cement, electricity and other industries.

The electric damper butterfly valve is mainly designed and manufactured with a new structure of centerline disc plate and short structural steel plate welding. It has compact structure, light weight, easy installation, small flow resistance, large flow volume, avoids the influence of high temperature expansion, and is easy to operate. There are no connecting rods, bolts, etc. in the body, reliable operation, and long service life. It can be installed in multiple positions and is not affected by the flow direction of the medium.

Precautions for installation

The installation position of the ventilation butterfly valve in the pipe network and the layout of the pipe network also have an impact on the use of the valve. Pipes with large smoke and dust are designed with a closed funnel at the valve opening end or the valve connection corner. Regular dust removal can prevent excessive dust accumulation, which is beneficial to The rotation of the butterfly plate. Several issues should be paid attention to when installing ventilation butterfly valves

1. When using metal gaskets, the load must be ensured uniformly to avoid the influence of temperature and dead weight or the stress generated by welding from bringing additional pressure to the valve and deforming the valve flange and pipeline.

2. When the valve is installed in a long pipeline, a support frame should be installed.

3. When installing the valve, attention should be paid to the flow direction of the medium, so that the opening direction of the butterfly plate is consistent with the flow direction of the pipeline medium, which is conducive to the self-cleaning effect of the medium flow rate.

4. Strengthen the protection of the overall insulation layer of the pipe network to keep the pipe wall temperature above the dew point, which can reduce low-temperature adhesive dust accumulation. If the pipe wall temperature is higher than the acid dew point of the flue gas, it can avoid the condensation of acid vapor on the heated pipe wall and control the generation rate of sulfur trioxide, so the valve will be more effective.

Ventilation butterfly valves can be installed in different positions depending on the design of the pipeline, such as horizontally,

Working principle

It uses the same material as the valve body to make a sealing ring, and adopts electric or pneumatic transmission. Its applicable temperature depends on the material selection of the valve body, and the nominal pressure is ≤0.6MPa. It is generally suitable for industrial, metallurgical, environmental protection and other pipelines for ventilation and regulating medium flow.

Its main features are:

Ther are some advantages:

1. Novel and reasonable design, unique structure, light weight, fast opening and closing.

2. Small operating torque, easy operation, labor-saving and dexterous.

3. Adopting suitable materials to meet low, medium and high medium temperatures and corrosive media.