Description

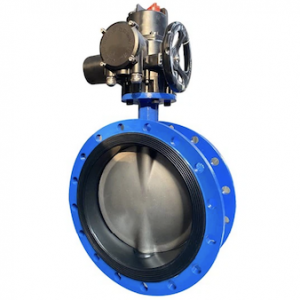

The fine smart electric valve actuator is equipped with Electric Cf8 Butterfly Valves, and its operating life is higher than the standard of similar products. It is small and light, easy to disassemble and repair, and can be installed in any position.

Features

Shell - The shell is made of hard aluminum alloy, anodized and polyester powder coated, with strong corrosion resistance and protection level of IP67.

Motor - Fully enclosed squirrel cage motor with small size, high torque, small inertia force, insulation grade F, built-in overheat protection switch to prevent overheating and damage to the motor.

Handle structure - The handle design ensures safety, reliability, labor saving and small size. When there is no power, the handle can be manually operated. When not in use, the wrench can be placed in the wrench clamp for easy use.

Indicator - The indicator is installed on the central axis to observe the valve position. The lens adopts a convex mirror design, which does not accumulate water and is more convenient for observation.

Dryer - used to control temperature, prevent condensation inside the actuator due to temperature and weather changes, and keep internal electrical components dry.

Sealing--Good sealing, standard product protection level is IP67.

The butterfly valve has a simple structure, small size, and light weight, and is composed of only a few parts. It can be quickly opened and closed by rotating 90°, which is simple to operate. At the same time, the valve has good fluid control characteristics. The butterfly plate of the butterfly valve is installed in the diameter direction of the pipeline. In the cylindrical channel of the butterfly valve body, the disc-shaped butterfly plate rotates around the axis, and the rotation angle is between 0° and 90°. When it rotates to 90°, the valve is fully open. When the flange butterfly valve is in the fully open position, the thickness of the butterfly plate is the resistance of the medium flowing through the valve body. Therefore, the pressure drop generated by the valve is very small, so it has better flow control characteristics. Butterfly valves have two sealing types: soft seal and metal seal. Elastic sealing valve, the sealing ring can be embedded in the valve body or attached to the periphery of the butterfly plate.

The electric flange butterfly valve has flanges at both ends of the valve body, which are connected to the pipe flange. The sealing performance is more reliable than that of the wafer-type butterfly valve. It is generally used in places with larger diameters or higher pressures, but the cost is higher than that of the wafer-type butterfly valve.

Flange connection

The main connection method of flange butterfly valve is flange connection. Flange connection is to fix the butterfly valve and pipe flange tightly together by bolts, which has the characteristics of strong connection and fastening force, easy installation and disassembly, and high reliability.

Flange connection is divided into two types: flat flange and raised flange. Flat flange connection is to fix the butterfly valve and pipe flange tightly together by bolts, which has the characteristics of strong connection and fastening force and high sealing reliability.

Flange butterfly valve is suitable for large-diameter and high-pressure pipeline systems. When connecting, a large number of bolts are required for fastening, so the connection reliability is high and it is suitable for strict occasions. In addition, flange butterfly valve also has the characteristics of simple structure, small size and light weight. It can be quickly opened and closed by rotating 90°, which is simple to operate and has good fluid control characteristics.

[Butterfly valve flange material]

No. 20, A105, Q235A, 12Cr1MoV, 16MnR, 15CrMo, 18-8, 321, 304, 304L, 316, 316L.

[Sealing surface form] Flat surface (FF), raised surface (RF), convex surface (M), concave surface (F), concave and convex surface (MF), tenon surface (T), groove surface (G), tongue and groove surface (TG), ring connection surface ( RJ).

[According to petrochemical industry standards] Threaded flange (PT), butt welding flange (WN), flat welding flange (SO), socket welding flange (SW), loose flange (LJ), flange cover (not noted).

[According to machinery industry standards] Integral flange, butt welding flange, plate flat welding flange, butt welding ring plate loose flange, flat welding ring plate loose flange, flanged ring plate loose flange, flange cover.

[According to national standards] Integral flange, threaded flange, butt welding flange, neck flat welding flange, neck socket welding flange, butt welding ring neck loose sleeve flange, plate flat welding flange, butt welding ring plate loose sleeve Flange, flat welded ring plate loose sleeve flange, flanged ring plate loose sleeve flange, flange cover.

[According to chemical industry standards] Integral flange (IF), threaded flange (Th), plate flat welding flange (PL), diameter butt welding flange (WN), neck flat welding flange (SO), socket welding flange (SW ), butt welding ring loose sleeve flange (PJ/SE), flat welding ring loose sleeve flange (PJ/RJ), lined flange cover (BL (S)), flange cover (BL).