Description

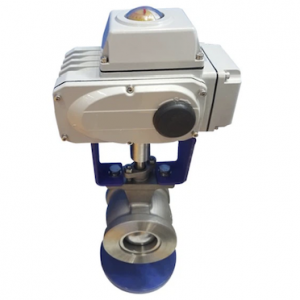

Telescopic Electric Cast Steel Butterfly Valve is a valve that uses a circular butterfly plate as the opening and closing part and rotates with the valve stem to open, close and adjust the fluid channel. It is a component used to achieve on-off and flow control of the pipeline system.

overview

At present, telescopic butterfly valves, as a component used to realize the on-off and flow control of pipeline systems, have been widely used in many fields such as petroleum, chemical industry, metallurgy, hydropower, etc. In the known butterfly valve technology, the sealing form mostly adopts a soft sealing structure, and the sealing materials are rubber, polytetrafluoroethylene, etc. Due to the limitations of structural characteristics, it is not suitable for industries such as high temperature resistance, high pressure resistance, corrosion resistance, and wear resistance. A relatively advanced butterfly valve is a three-eccentric metal seal butterfly valve. The valve body and valve seat are connected components, and the valve seat sealing surface layer is welded with heat-resistant and corrosion-resistant alloy materials. The multi-layer soft stacking sealing ring is fixed on the valve plate. Compared with the traditional butterfly valve, this butterfly valve has the advantages of high temperature resistance, easy operation, no friction when opening and closing, and the seal is compensated as the torque of the transmission mechanism increases when closing, which improves the sealing performance of the butterfly valve and extends its service life.

Compact and lightweight

Easy to disassemble and repair, and can be installed in any position

Simple structure

Compact, low operating torque, quick opening with 90 degree rotation

Flow characteristics

Flow characteristics tend to be linear, with good regulation performance

Pinless structure

The connection between the butterfly plate and the valve stem adopts a pin-free structure, which overcomes the possible internal leakage points

Two-way sealing

The seal is replaceable and the seal is reliable to achieve bidirectional sealing.

Spray coating

The butterfly plate can be sprayed with coatings such as nylon or polytetrafluoroethylene according to user requirements.

Structural features

The telescopic butterfly valve has the characteristics of simple structure, small size, light weight, low material consumption, small installation size, fast switching, 90° reciprocating rotation, small driving torque, etc. It is used to cut off, connect and adjust the medium in the pipeline, and has good fluid control characteristics and closing sealing performance. When the telescopic butterfly valve is in the fully open position, the thickness of the telescopic butterfly valve is the only resistance when the medium flows through the valve body. Therefore, the pressure drop generated by the valve is very small, so it has good flow control characteristics. The telescopic butterfly valve has two sealing types: elastic seal and metal seal. The valve with metal seal of the telescopic butterfly valve generally has a longer life than the valve with elastic seal, but it is difficult to achieve complete sealing. Metal seals can adapt to higher working temperatures, while elastic seals have the defect of being limited by temperature. If the telescopic butterfly valve is required to be used as a flow control, the main thing is to correctly select the size and type of the valve. The structural principle of the telescopic butterfly valve is particularly suitable for making large-diameter valves. Telescopic butterfly valves are not only widely used in general industries such as petroleum, gas, chemical industry, and water treatment, but also in the cooling water system of thermal power plants. Commonly used telescopic butterfly valves include wafer-type butterfly valves, flange-type butterfly valves, and butt-welded butterfly valves. The wafer-type butterfly valve is connected between two pipe flanges with studs; the flange-type butterfly valve is a valve with flanges, and the flanges at both ends of the valve are connected to the pipe flanges with bolts; the two end faces of the butt-welded butterfly valve are welded to the pipe. The streamlined design of the butterfly plate reduces the fluid resistance loss, which can be regarded as an energy-saving product. The valve stem is a through-rod structure, which has been tempered and has good comprehensive mechanical properties and corrosion resistance and abrasion resistance. When the butterfly valve is opened and closed, the valve stem only rotates instead of lifting and lowering. The packing of the valve stem is not easy to be damaged and the seal is reliable. It is fixed with the butterfly plate cone pin, and the extended end is designed to prevent the valve stem from bursting out when the valve stem and the butterfly plate are accidentally broken.

Precautions

1. Before assembly, check that all parts of the electric butterfly valve are intact and the model is correct, and check that there is no debris in the valve body.

2. Put both the valve and the actuator in the closed state.

3. Install the actuator on the valve, and then check whether the screw holes are aligned and there is not much deviation, and then tighten the screws.

4. After installation, debug the butterfly valve and observe the opening and closing of the telescopic butterfly valve. If it is found during the debugging process that the valve is a little strenuous at the beginning of the opening and closing process, and then normal, it is necessary to reduce the stroke until the valve opens and closes smoothly and closes without leakage.

5. The butterfly valve should be kept dry before installation and should not be stored in the open air

6. Before installing the butterfly valve, check the pipeline to ensure that there is no foreign matter such as welding slag in the pipeline

7. The manual opening and closing resistance of the telescopic butterfly valve body is moderate, and the torque of the butterfly valve matches the torque of the selected actuator.

8. The flange specifications for the connection of the telescopic butterfly valve are correct, and the pipe clamp flange is consistent with the butterfly valve flange standard. It is recommended to use a special flange for butterfly valves, and flat welding flanges must not be used.

9. Confirm that the flange welding is correct. After the butterfly valve is installed, the flange must not be welded again to avoid scalding the rubber parts.

10. The installed pipeline flange must be aligned and aligned with the butterfly valve.

11. Install all flange bolts and tighten them by hand. Confirm that the butterfly valve and the flange are aligned, and then carefully open and close the butterfly valve to ensure flexible opening and closing.

12. Open the valve completely and tighten the bolts in diagonal order with a wrench. No gasket is required. Do not tighten the bolts too much to prevent serious deformation of the valve ring and excessive opening and closing torque.